German Robot Can Fully Recycle Any Electronic Device

Tackling the Growing E-Waste Crisis

By 2030, the world could generate up to 74 million tons of electronic waste. To combat this issue, researchers at the Fraunhofer Institute are developing iDEAR, an advanced robotic system that combines artificial intelligence and automation to efficiently dismantle and recycle electronic devices. This system can handle everything from old computers to broken household appliances, making e-waste management more effective and less labor-intensive.

How iDEAR Works

The iDEAR system aims to provide a smart, autonomous solution for breaking down electronic devices in a safe and efficient manner. It processes all types of e-waste, analyzing and sorting them before disassembly.

- Identification & Sorting

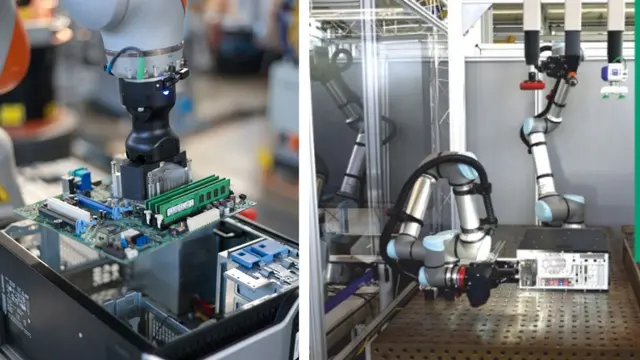

When e-waste arrives at a recycling facility, it is scanned and categorized. Optical sensors and 3D cameras powered by AI assess the type of device, detect damage, and determine whether full disassembly is needed or only specific components should be extracted. - Automated Disassembly

Once the system determines the best approach, the robotic arm begins dismantling the device. The robot can lift, cut, extract, and separate components, press buttons, bend structures, and even sever wires with precision. - Technological Advancements

Scientists have already developed a working prototype capable of recognizing computers and creating their digital twins. The system has successfully extracted motherboards from PCs, a complex task that marks a major milestone. The next goal is to integrate all processes into a single demonstrator, ensuring seamless automation.

iDEAR: A Sustainable Future for E-Waste Recycling

Currently, over 80% of electronic waste ends up in landfills or incinerators, releasing hazardous chemicals into the environment. Traditional recycling methods require extensive engineering efforts and are usually limited to specific product categories. iDEAR, however, leverages AI-driven data analysis to handle a broad range of devices in real time without requiring excessive manual labor.

Researchers believe that as the system evolves, it could be applied to an even wider range of electronic equipment, making recycling more efficient and environmentally friendly.